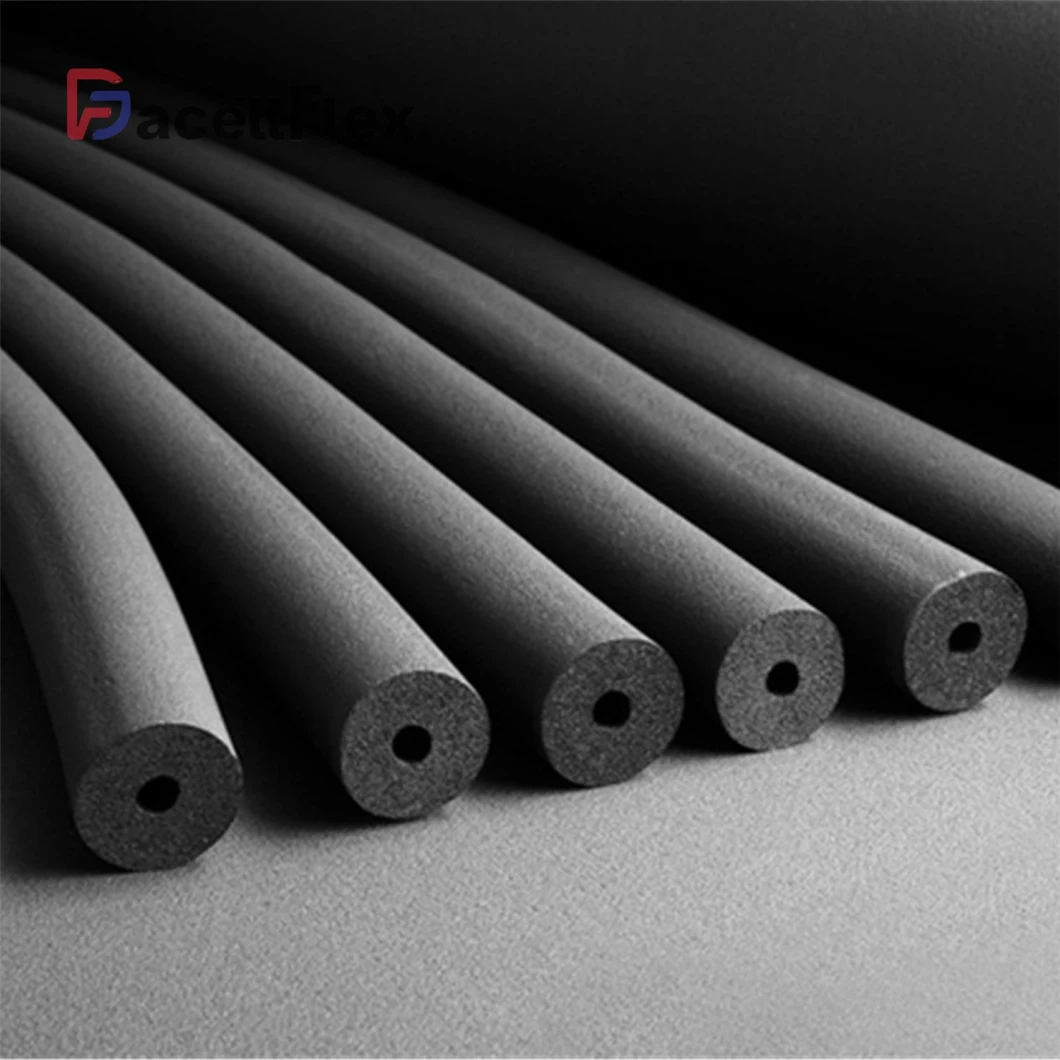

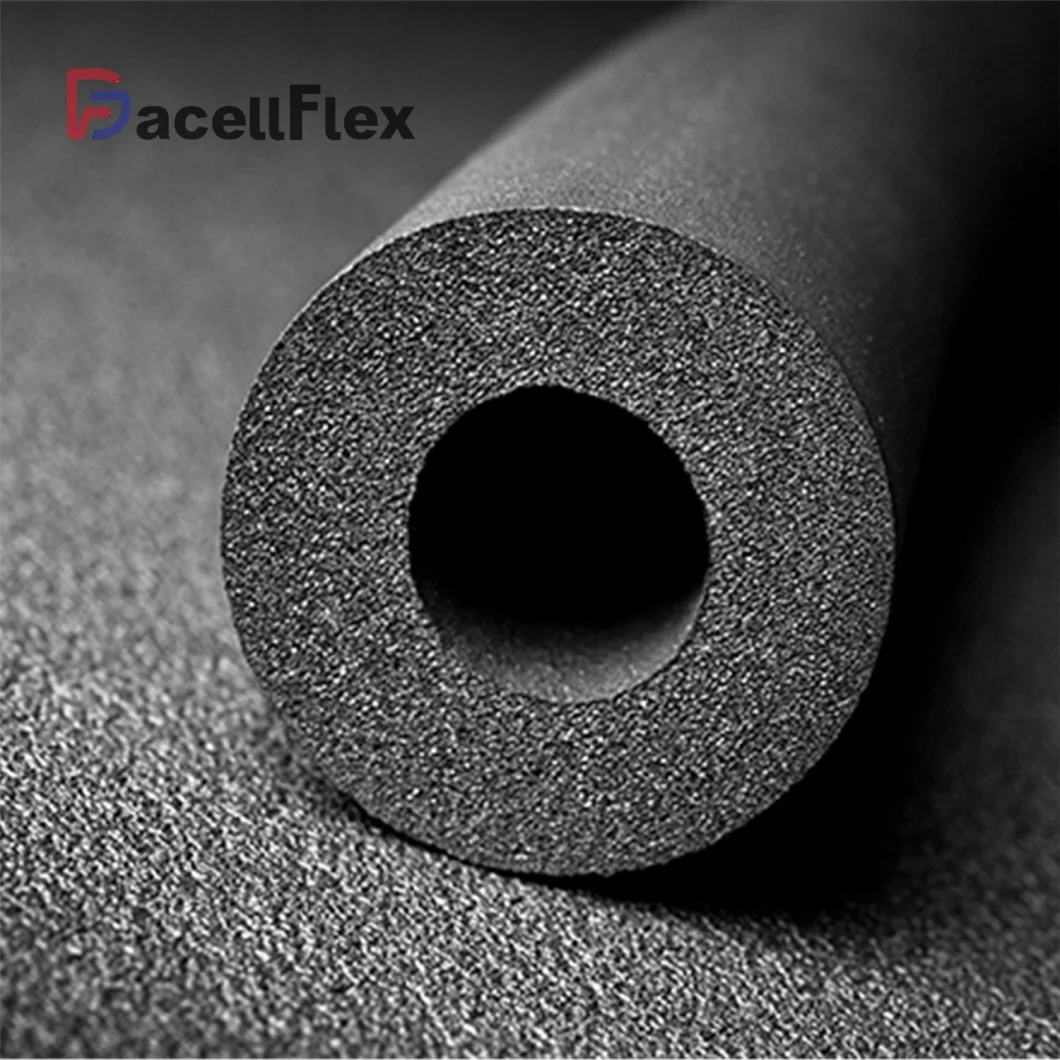

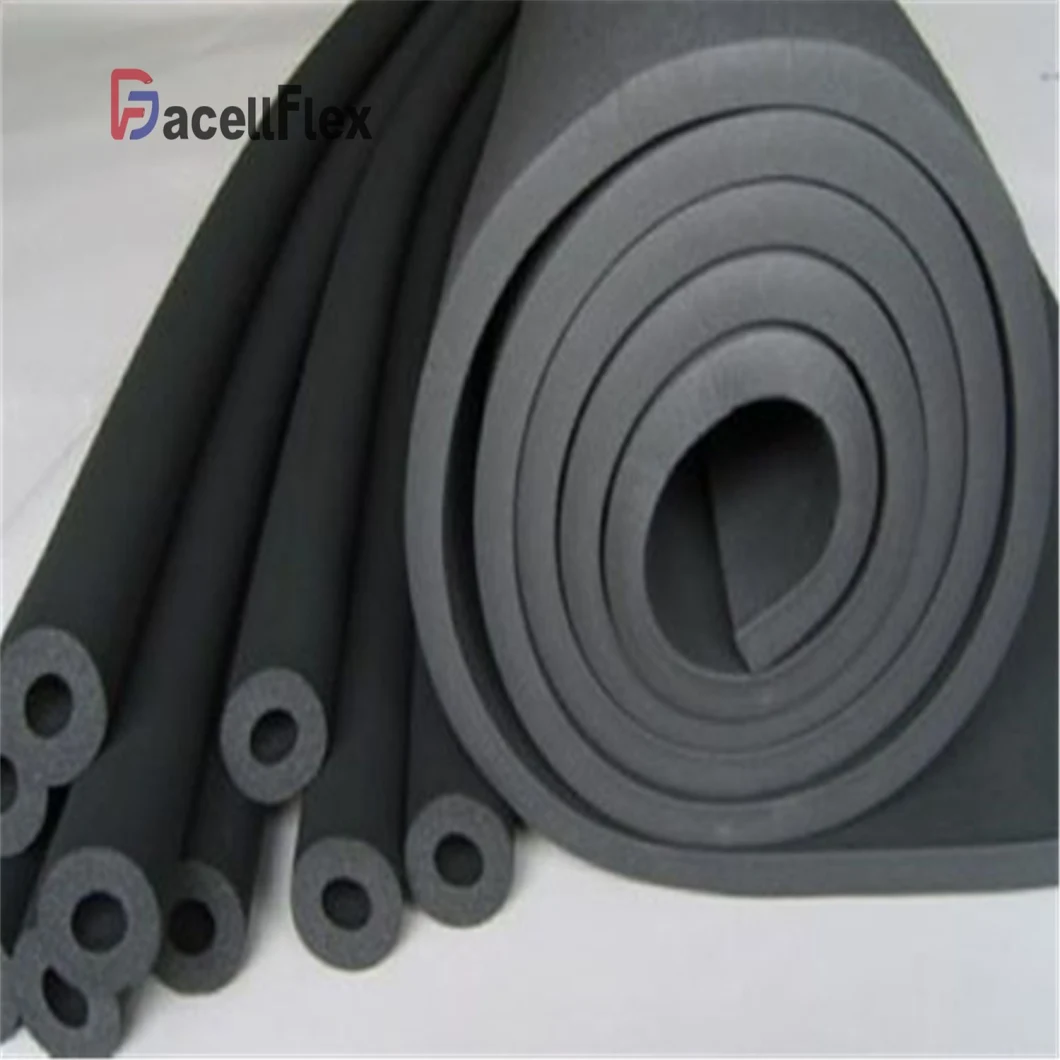

DACELLFLEX thermal insulation tube uses NBR (nitrile-butadiene rubber) as main raw material for foaming and become a fully closed cell of flexible rubber foam insulation materials without any fiber materials such as HCHO and CFCs which are bad for the ozonosphere. It is black material with excellent work performance of product, make widely used in various public places, industrial workshop, clean room, medical and educational institutions.

Lower conductivity

DACELLFLEX Insulation Material comprehensively accepted the most advanced international "gel" foaming technology, 100°o full cell, well distributed small cell structure that ensures very low conductivity A w 0.033w/(m.k) at OC.

Higher moisture resistance

DACELLFLEX Insulation Material is of cell structure, excellent ability of water vapor permeability, moisture resistance N10000, make materials become both of moisture proof layer and thermal insulation layer that ensure the long durabilty "of the material properties up to around 20 years life time.

High security fire prevention function

We use advanced and special environment protecting formula without any halogen and the fireproof medium is well distributed in every cell structure. No unhealthy gas while burning, reach the standard of security level 3 which is in accordance with national new standard Class B in the GB 8624-2006. Our products offer good performance in the smoking, burning drops and gas toxicity, which is the most reasonable insulation material for our customers.

| SPECIFICATIONS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Surface density | Color | Type | Density | ||||||||

| 80 (Kg/m3) | Black | Air Conditioning, Refrigeration, Chiller Insulation | 80 (Kg/m3) | ||||||||

| Bumping performance | Water absorption in vacuum | Thermal Conductivity | Temperature Limit | ||||||||

| Grade B | ≤ 8% | 0.037W/mk | -40° -105° | ||||||||

Closed Cell NBR Rubber Foam Insulation

- The below average physical properties are values obtained in accordance with accepted test methods.

- At -40°C, Dacellflex Closed Cell Insulation becomes hard and as temperature drops below -40°C will be increasingly brittle; however this hardening chracteristic does not affect thermal or water vapour permeability.

- The Fire rating standard method of tests conducted under controlled laboratory conditions is a measure of a material to spread flame when compared to a known standard and is not intended to reflect hazards presented by this or any material under actual fire conditions.

| Average Physical Properties | Rating | Test Method | |

|---|---|---|---|

| Density | 65 kg/m3 to 80 kg/m3 (Tubing) | ASTM D1667 | |

| 55 kg/m3 to 80 kg/m3 (Roll) | |||

| Thermal Conductivity ('K' Value) at 20˚C mean temperature | 0.035 W/mk | ASTM C518 | |

| Service Temperature C | -50˚C to + 150˚C | ||

| Water Absorption (% by weight) | < 3% | ASTM D1056 | |

| Water Vapour Permeability Perm - in Max | 0.0119 Perm-inch | ASTM E96 | |

| Water Vapour Resistance µ Factor | > 11,000 | DIN 52615 - 73 | |

| Thermal Stability (% shrinkage) | 7 Days 200˚F | 0.20 % | ASTM C534 |

| 7 Days 200˚F | 3.30 % | ||

| Average Fire Propagation Average Surface Spread of Flame | Class 0 Class 1 | BS 476 PART 6 BS 476 PART 7 | |

| Flammability | FM Approved | Class: 4924 | |

| V-), 5VA, HF-1 | UL 94 | ||

| Reaction To Fire | Self-Extinguishing, No Dripping | ||